емкости для вина

Емкости для виноделия из нержавеющей стали от Роза ветров™

Ассортимент емкостей из пищевой нержавейки, применяемых в производстве вина и его хранении, достаточно большой. В продаже имеются бочки разного объема, до 50000 л., с плоскими и коническими днищами, со стационарными ножками, со сливными кранами и другие.

Профессиональная емкость для вина 130 л из нержавеющей стали AISI 304

Представляем уникальную емкость для вина объемом 130 литров, специально разработанную для виноделов, ценящих качество, надежность и функциональность. ► Смотреть на YouTube

Основные характеристики:

Материал: зеркальная нержавеющая сталь AISI 304, обеспечивающая высокую коррозионную стойкость и легкость в уходе.

Толщина стенок: 2 мм, что позволяет эффективно зачищать и полировать сварочные швы, включая шов дна.

Герметичная крышка: диаметром 400 мм с уплотнительной резинкой и возможностью установки гидрозатвора.

Косое дно: обеспечивает полный слив без остатка.

Краны:

♦ нижний кран ¾ дюйма для полного слива;

♦ верхний кран ½ дюйма для забора осветленного вина.

Кольцо устойчивости: предотвращает опрокидывание и обеспечивает дополнительную стабильность.

Габариты: высота без учета люка — 850 мм, диаметр — 500 мм.

Стоимость: 15 000 грн.

Изготовление под заказ: возможность производства емкостей других типоразмеров по индивидуальным требованиям.

Преимущества конструкции:

Герметичность: обеспечивает длительное хранение вина без риска окисления.

Гибкость использования: возможность установки гидрозатвора для ферментации или герметичного закрытия для хранения и осветления вина.

Простота обслуживания: зеркальная поверхность и качественные швы облегчают процесс очистки и дезинфекции.

Универсальность: подходит как для домашних виноделов, так и для небольших винодельческих хозяйств.

Преимущества перед другими видами тары:

-

В отличие от пластиковых или стеклянных емкостей, данная нержавеющая емкость:

-

не впитывает запахи и не взаимодействует с содержимым;

-

обеспечивает стабильную температуру и защиту от внешних факторов;

-

имеет долгий срок службы и устойчивость к механическим повреждениям;

-

легко поддается санитарной обработке.

Емкости из нержавеющей стали широко используются в производстве вина по следующим причинам:

♦ Безопасность для продукта: нержавеющая сталь является нейтральным материалом, который не взаимодействует с вином, сохраняя его качество и вкус.

♦ Устойчивость к коррозии: Винные напитки имеют низкий уровень pH, что может вызвать коррозию металлических поверхностей. Емкости из нержавеющей стали обладают высокой коррозионной стойкостью, что обеспечивает длительный срок эксплуатации и высокий уровень гигиены.

♦ Легкость очистки: поверхность нержавеющей стали гладкая и легко моется, что обеспечивает высокий уровень гигиены и делает емкости из нержавеющей стали легкими в уходе. Это особенно важно при производстве вина, где чистота и гигиена имеют решающее значение для сохранения качества продукта.

♦ Прочность и долговечность: Нержавеющая сталь является прочным материалом и может выдерживать высокие давления и температуры, что важно при производстве вина, где нужно обеспечивать правильную температуру и давление для оптимального качества.

♦ Экологически безопасность: Нержавеющая сталь является перерабатываемым материалом, что делает ее экологически безопасной и удобной для переработки и утилизации.

В целом, емкости из нержавеющей стали - это надежное и безопасное решение для производства вина, которое обеспечивает высокий уровень гигиены, сохраняет качество продукта и имеет длительный срок эксплуатации.

Бочки для вина с плавающей крышкой

|

Бочки для вина с плавающей крышкой - это традиционный способ хранения и созревания вина, который используется уже много лет. Крышка на такой бочке называется "шляпой", так как она плавает на поверхности вина и накрывает его, чтобы предотвратить доступ воздуха и защитить вино от окисления.

|

Преимущества бочек для вина с плавающей крышкой включают:

♦ Улучшенный контроль за процессом созревания: благодаря плавающей крышке, можно контролировать уровень заполнения бочки вином, что позволяет более точно регулировать концентрацию алкоголя и других химических элементов в процессе созревания.

♦ Меньший риск окисления вина: крышка на бочке защищает вино от окисления, что может привести к потере вкуса и аромата.

♦ Более равномерное созревание вина: благодаря шляпе, вино в бочке может равномерно созревать во всех направлениях, что важно для создания высококачественного продукта.

♦ Удобство использования: бочки для вина с плавающей крышкой легче в использовании, чем традиционные бочки, потому что нет необходимости использовать кран для выкачивания вина, что может снизить риск загрязнения вина.

♦ Традиционный вид: такие бочки создают традиционный вид и атмосферу, что может быть важно для производителей, которые стремятся сохранить традиционный вид производства вина.

|

Бочки для вина из нержавеющей стали с плавающей крышкой - это современная альтернатива традиционным бочкам из дуба с плавающей крышкой.

|

Такие бочки обладают рядом преимуществ по сравнению с традиционными бочками из дуба, включая:

♦ Длительность службы: бочки из нержавеющей стали обладают более длительным сроком службы, чем традиционные бочки из дуба, так как не подвержены влиянию микроорганизмов и не требуют периодической обработки.

♦ Легкость в уходе: бочки из нержавеющей стали легко чистятся и обеззараживаются, что делает их более гигиеничными и удобными в уходе.

♦ Улучшенный контроль за процессом созревания: как и в случае с традиционными бочками с плавающей крышкой, бочки из нержавеющей стали с плавающей крышкой позволяют контролировать уровень заполнения бочки вином, что улучшает контроль за процессом созревания.

♦ Меньший риск окисления вина: так как бочки из нержавеющей стали герметичны, они защищают вино от окисления и сохраняют его свежесть и аромат.

♦ Эффективность при хранении больших объемов: бочки из нержавеющей стали могут использоваться для хранения и созревания больших объемов вина, что делает их более эффективными, чем традиционные бочки из дуба.

♦ Регулируемая температура: бочки из нержавеющей стали могут быть оснащены системами контроля температуры, что позволяет производителям вина точно настроить процесс созревания и достичь желаемого вкуса и аромата вина.

♦ Отсутствие неприятного запаха: новые бочки из дуба могут иметь неприятный запах, который может передаваться вину. Бочки из нержавеющей стали не имеют запаха, что делает их более привлекательными для производителей вина.

♦ Более точный контроль за качеством: бочки из нержавеющей стали с плавающей крышкой могут быть оснащены системами контроля уровня кислорода и других факторов, что позволяет более точно контролировать процесс созревания и обеспечить высокое качество вина.

♦ Удобство транспортировки: бочки из нержавеющей стали могут быть произведены в разных размерах и легко транспортируются, что делает их более удобными в использовании на производственных предприятиях и для транспортировки вина.

♦ Сохранение естественного вкуса: так как бочки из нержавеющей стали не взаимодействуют с вином, они сохраняют его естественный вкус и аромат, что может быть важно для производителей, которые стремятся сохранить уникальный вкус и аромат своего вина.

♦ Экологическая устойчивость: бочки из нержавеющей стали могут быть переработаны после использования, что делает их более экологически устойчивыми, чем традиционные бочки из дуба.

В целом, бочки для вина из нержавеющей стали с плавающей крышкой представляют собой современный и эффективный способ хранения и созревания вина, обладающий рядом преимуществ перед традиционными бочками из дуба. Однако, выбор между ними зависит от индивидуальных потребностей и предпочтений производителя вина.

Конструкция

Бочка нержавеющая с плавающей крышкой состоит из:

♦ Цилиндрической емкости (собственно бочка) для сырья или продукта.

♦ Плавающей крышки, по окружности которой есть надувная силиконовая камера.

♦ Насоса с фиксатором на бочку и манометром.

♦ Клапана для стравливания избыточного давления (при брожении).

♦ Набора дополнительных деталей: соединительный шланг, штуцеры, плетеный шнур, хомуты подпружиненные.

Емкость делается из пищевой нержавейки AISI 304, толщиной, в зависимости от объема, от 0,6 до 6 мм. Внутренняя поверхность – с электрохимической зеркальной полировкой, наружная обработана в виде «чешуи».

Сварка выполняется по технологии TIG последнего поколения, без контактных и сварочных материалов, в инертном газе, с протравкой и автополировкой швов.

В комплект может входить верхняя негерметичная крышка, для защиты от пыли и мусора. А также заглушка, которая, при необходимости, ставится вместо сливного крана.

Стандартная бочка на 200 литров делается высотой 840 мм, диаметром 540 мм. Весит 9,8 кг.

Принцип действия

Работает бочка с плавающей крышкой следующим образом. Емкость должна находиться на устойчивой опоре или ровной поверхности так, чтобы обеспечивалась горизонтальность доньев.

В бочку заливается вино в количестве не менее 5 л. Плавающая крышка опускается на зеркало. Воздух в камеру нагнетается насосом. После этого, содержимое бочки переходит в режим хранения – взаимодействие с наружной атмосферой исключено.

Для слива содержимого или его дозированного отбора, надо сбросить давление при помощи клапана. После этого можно будет открыть расположенный в нижней части емкости кран и слить некоторый объем продукта. Потом краник закрывается, крышка снова кладется на поверхность вина, в силиконовую камеру опять накачивается воздух.

Кеги, в том числе из нержавейки, ранее использовались только для пива. Связано это было с несовершенством технологии хранения виноградных напитков в емкостях данного типа. Но, в результате многочисленных экспериментов, был определен порядок мытья и последующего заполнения кегов. После чего их начали использовать и для вина.

В технологиях по очистке и последующей стерилизации кегов применяются инертные газы. В емкостях для пива система труб для наполнения не отличается высокой степенью герметичности. Она пропускает определенное количество кислорода. Для винных нержавеющих бочек это недопустимо.

Инертные газы аргон или азот нужны для того, чтобы не происходило окисление напитка. Кроме того, если вино хранится в металлической бочке, то там, как и в бутылке, должно быть некоторое количество растворенного СО2. Углекислый газ необходим, чтобы вкусовые и ароматические характеристики жидкости сохранялись на прежнем уровне.

Кроме того, есть рекомендация по применению смеси небольшого количества двуокиси углерода с азотом. Она похожа на ту, которую использует Гиннес.

Бочки из нержавейки для вина – это современный материал многоразового пользования, прочный, долговечный и гигиеничный. Их многочисленные достоинства настолько превышают недостатки, что можно не сомневаться – такие емкости будут пользоваться все большей популярностью среди виноделов.

Нержавеющая сталь

Бочка из нержавеющей стали подходит для производства и хранения вина потому, что она нейтральна к находящимся в сусле кислотам и спирту. Этот материал не только самый прочный и долговечный, среди применяющихся в виноделии, у него есть и другие достоинства.

При помощи емкость из нержавейки устраняется проблема разбитых бутылок и некачественных пробок. А сам напиток после открытия можно долго держать свежим, с сохранением вкуса и запаха. Не секрет, что всем солидным заведениям, продающим вино на разлив, приходится решать проблему его хранения. Открытая бутылка не обязательно будет расходована до конца дня. Из-за этого на последних рюмках может исчезнуть не только оригинальный запах, но также и вкус.

Потому, в конце смены, остатки вина сливают из бутылок в специальные хранилища. Наличие емкости из нержавейки, подключенной к сливному кранику и оборудованной специальной системой для хранения, намного упрощает процесс. Да и дегустационную порцию клиенту можно будет налить без проблем, для этого не потребуется открывать бутылку.

Кроме того, нержавеющая сталь – это более подходящий, по сравнению с деревом, материал для созревания белых вин. В таких емкостях лучше сохраняется «летняя» свежесть аромата и приятность вкуса.

Особо хотелось бы отметить полезность такого изделия из нержавейки, как бочка с плавающей крышкой. Это идеальная емкость в тех случаях, когда надо заполнить ее доверху, чтобы исключить контакт напитка с кислородом, например, на этапе тихого брожения вина.

Технология виноделия.

Настоящее вино изготовляют только из винограда. Технические сорта винограда, идущие на производство вин, должны удовлетворять особым требованиям: хорошо накапливать сахар, иметь умеренную кислотность, хорошо поддаваться переработке, созревать в разное время.

Белые вина готовят из винограда с повышенным содержанием ароматических веществ и кислот, красные - с высоким содержанием красящих веществ и фенольных соединений. Высокосахаристые и ароматичные сорта используются для выработки десертных и ликерных вин. Для крепких вин хороши высокосахаристые сорта с пониженным содержанием кислот, большим количеством экстрактивных и фенольных веществ.

Для виноградных вин, изготовленных без каких-либо добавок, иногда применяется наименование «натуральное вино». Обычно это сухие и полусухие вина. С использованием различных добавок изготовляются ароматизированные вина. Это группа вин, приготовленная смешением виноматериалов, этилового спирта-ректификата или виноградного спирта, сахарного сиропа и настоев ингредиентов, придающих им специфический вкус и аромат.

Основным типом ароматизированных вин является вермут. Для ароматизации вин, кроме настоев ингредиентов, используют спиртовые растворы эфирных масел (эссенции), душистых веществ (например, ванилина), бальзамы и ароматные спирты. В старину такие вина называли пряными. Из других добавок интересны витамины.

Производства вина включает две стадии. На стадии первичного виноделия выполняются все операции, связанные с переработкой винограда, которые завершаются получением молодого вина. На стадии вторичного виноделия виноматериал обрабатывают, выдерживают и разливают в бутылки.

Собранный виноград поступает на дробление и прессование. Для получения шампанского его иногда прессуют гроздями. Сусло, вытекающее из винограда при легком отжиме без прессования, а также вино из него называется самотеком.

Для выработки белых вин сусло быстро отделяют от мезги. Такая технология называется переработкой по белому способу. Самотек и сусло первого давления идет на приготовление высококачественных вин, а последующие прессовые фракции - на выработку ординарного вина.

При переработке по красному способу необходимо извлечь красящие вещества из кожицы виноградных ягод. Для этого применяют разные приемы: нагрев мезги, брожение сусла на мезге, спиртование и брожение мезги с извлечением красящих веществ и другие приемы.

С античного времени известно сульфитирование сусла введением небольшого количества двуокиси серы с целью подавление вредных микроорганизмов. Без этого приема невозможно получить стабильное вино, способное к хранению. Далее сусло осветляют и направляют на брожение.

Брожение проводится на чистой культуре винных дрожжей или на природных дрожжах. Если надо получить сухое вино, то сахар сбраживается полностью. При выработке полусладких или сладких вин брожение принудительно останавливают разными способами: спиртованием, холодом или теплом.

После окончания брожения вино осветляется, его снимают с дрожжей путем переливания. Во время переливки смешивают вина одного типа и сорта. Период от конца брожения до первой переливки называется формированием вина. Для производства специальных вин используются особые технологические приемы.

Полученное молодое вино направляют на выдержку (см. Выдержка вина), а после окончания выдержки зрелое вино - на розлив, который обычно производится на автоматических линиях с минимальным доступом воздуха.

Таковы основные технологические процессы производства вина.

Классификация вин.

Все вина делятся на сортовые и купажные. Сортовые вина изготавливаются из одного сорта винограда, купажные - из двух и более виноматериалов разных сортов винограда. К купажным винам относятся также ароматизированные вина.

Вина подразделяются на тихие и содержащие диоксид углерода, то есть углекислоту. К тихим винам относятся столовые (сухие, полусухие и полусладкие), крепкие, десертные (полусладкие, сладкие и ликерные), ароматизированные, к содержащим углекислоту - шампанское и игристое. Углекислота дает игру вина - интенсивное выделение большого количества мелких пузырьков углекислого газа.

Вина, получаемые в результате полного (сухие) или частичного (полусухие и полусладкие) брожения называют столовыми. При их приготовлении не разрешается введение в сусло или вино каких-либо посторонних веществ, кроме разрешенных законом, в том числе спирта. Поэтому их еще называют натуральными. Сухие столовые вина содержат 9-14 % об. этилового спирта и до 0,3 г./100 мл. сахара. Полусухие - 9-12 % об. спирта и 1-2,5 г./100 мл. сахара. Полусладкие- 9-12 % об. спирта и 3-8 г./100 мл. сахара.

Крепленые вина изготовляются с использованием этилового спирта, главным образом, ректификата или виноградного дистиллята. По содержанию спирта они подразделяются на крепкие - 17-20 % об. спирта (иногда и более), из которых спирта естественного брожения не менее 3 % и десертные - 12-17 % и 1,2 %. Содержание сахара в крепких винах - 1-14 г./100 мл. К крепким винам относятся портвейн, мадера, малага, марсала, херес.

Натуральные и крепленые вина, содержащие 12-17 % об. спирта и 2-35 г./100 мл. сахара именуются десертными. Доля спирта естественного брожения здесь не менее 1,2 % об. Десертные вина бывают полусладкими - 14-16 % об. спирта, 5-12 г./100 мл. сахара; сладкими - 15-17 % об. спирта, 14-20 г./100 мл. сахара; ликерными - 12-17 % об. спирта, 21-35 г./100 мл. сахара. К последним относится большинство мускатных, токайских вин, малага.

Шампанское обычно содержит 10,5-12,5 % об. спирта и в зависимости от содержания сахара подразделяется на брют (до 1 г./100 мл. сахара), сухое (до 3 г./100 мл. сахара), полусухое (до 5 г./100 мл. сахара), полусладкое (до 8 г./100 мл. сахара) и сладкое (до 10 г./100 мл. сахара).

Игристые вина делятся на красные (11-13,5 % об. спирта, 7-8 г./100 мл. сахара), розовые (10,5-12,5 % об. спирта, 6-7 г./100 мл. сахара), мускатные (10,5-12,5 % об. спирта, 9-12 г./100 мл. сахара) и шипучие (9-12 % об. спирта, 3-8 г./100 мл. сахара).

Ароматизированные вина, как правило, содержат 16-18 % об. спирта и от 6 до 16 г./100 мл. сахара.

По окраске вина разделяются на белые, розовые и красные. Французы говорят, что белое вино создано для утоления жажды, красное - для наслаждения, розовое - для любви.

Прозрачность вина зависит от присутствия в нем мелких частиц и характеризует его внешний вид. Высококачественные бутылочные вина должны быть кристаллически прозрачны, вина бочкового разлива - также прозрачны.

По качеству вина разделяются на ординарные, марочные и коллекционные.

К специальным относятся вина, полученные в результате применения специальных приемов изготовления и имеющие характерные свойства в букете и вкусе: портвейн, мадера, херес, марсала, малага, токай, кагор, игристые вина, ароматизированные вина и другие.

Качество и этапы жизни вина.

Качество вина определяется прежде всего его гармонией, то есть взаимным соответствием элементов качества: окраски, аромата, вкуса. Различают гармонию отдельных элементов - аромата, вкуса, а также гармонию вина в целом.

По этому признаку вино характеризуется как изысканное, тонкое, слаженное, гармоничное, круглое или простое, ординарное, усталое, негармоничное, грубое, разлаженное. При выдержке, как правило, вино становится более гармоничным.

Ординарные вина выпускаются без выдержки в возрасте до одного года, но не ранее чем через 3 месяца после переработки винограда. Готовятся из винограда одного сорта или смеси сортов.

К высококачественным относятся марочные вина - выдержанные высококачественные вина, вырабатываемые по специальной технологии из одного или немногих, утвержденных для каждой марки, сортов винограда, выращиваемого в определенных районах, микрорайонах или участках.

Основные требования, которые предъявляются к марочным винам - постоянные, сохраняющиеся из года в год характерные особенности каждой конкретной марки вина и высокие вкусовые качества, обусловленные сортом винограда, технологией и выдержкой, в процессе которой вина созревают и стареют. Продолжительность выдержки таких вин в зависимости от типа составляет от 1,5 до 4 лет и более.

Оценка качества вина производится путем его дегустации.

Вино проходит этапы рождения, созревания и старения, но со временем происходит отмирание вина - его разрушение, потеря характерных качеств, товарного вида, у вина изменяется окраска, выпадает осадок, возникают неприятные запах и вкус. Процесс отмирания у разных вин протекает с различной скоростью - быстро у столовых, медленнее у крепких и десертных вин. Срок жизни белых столовых вин и шампанского - 3-5 лет, красного столового - 5-10 лет, десертных - 18-20 лет. Срок жизни крепких и высокосахаристых (ликерных) вин очень велик и может превышать 100 лет.

Технология виноделия, научная дисциплина, изучающая способы и приемы переработки винограда на виноматериалы, а также обработки, выдержки и розлива вин. Базируется на данных химии вина, микробиологии виноделия, биохимии виноделия, ампелографии и др. дисциплин.

Задачей технологии виноделия является выявление физико-химических, биохимических и др. закономерностей процессов приготовления вин различных типов с целью установления наиболее эффективных технологий. Основоположником науки о вине считается Луи Пастер.

Химия вина, энохимия, прикладная наука, изучающая химический состав винограда и вина, методы анализа и химические процессы, происходящие на разных стадиях приготовления вина. Исторически химия вина как наука развилась из технологии виноделия.

Простейшее определение сахаристости винограда и крепости вина производилось в Греции, Египте и др. странах Средиземноморья еще до н. э. Основы современной химии вина заложили в 19 в. Луи Пастер (по брожению сусла и созреванию вина). П. Бертло (по роли кислорода в процессе созревания вина), Д. И. Менделеев (по составлению спиртометрических таблиц).

При изучении химический состава вин, а также процессов, происходящих на различных стадиях их приготовления, используются современные химические и физико-химический методы исследования, в т. ч. газожидкостная, жидкостная и ионообменная хроматография, гель-фильтрация, диск-электрофорез, ядерный магнитный резонанс, электронный парамагнитный резонанс, УФ- и ИК-спектроскопия, атомная абсорбция и др.

В винограде и винах идентифицировано более 500 компонентов, для значительной части которых установлена роль в процессах виноделия. Это позволило правильнее оценить существующую технологию приготовления разных типов вин и разработать ряд новых, более эффективных технологических приемов.

От лозы к бутылке — технология изготовления вина.

|

Работа винодела начинается задолго до сбора урожая. Хороший винодел трудится в течение всего года, ежедневно посещая виноградник и используя все свои знания и опыт, чтобы вырастить качественный продукт для изготовления вина. Винодел подготавливает землю к зиме, удаляет чересчур старые лозы, если виноградник расположен на склоне (а это чрезвычайно распространенное явление), виноделу приходится поднимать вверх почву, опустившуюся за год из-за дождей.

|

|

Необходимо обрезать виноградник — это регулирует плодоношение лоз и влияет на качество винограда. Как обрезать — зависит от типа земли, климата. Это знание тоже приходит с опытом. Также винодел удобряет почву, удаляет сорняки, борется с вредителями и болезнями винограда, защищает его от ранних заморозков. И только потом наступает сам процесс сбора урожая, за которым и следует изготовление вина.

|

|

Для изготовления красного вина используется виноград красных сортов, его собирают, доставляют в винодельню и подвергают переработке. Сначала виноград идет на дробилку-гребнеотделитель, где ягоды давят и отделяют гребни.

|

Во время этой операции не должны быть повреждены семена винограда — в этом случае у вина может появиться слишком терпкий неприятный вкус.

Раздавленный виноград помещается в чаны, где в него вводят специальные вещества, которые убивают бактерии. Затем происходит брожение.

|

Виноградное вино может быть получено только в результате спиртового брожения раздавленного винограда (вместе с кожурой или отдельно сока). Брожение — сложный химический процесс, который вызывают дрожжи, обладающие способностью разлагать сахар на спирт и углекислый газ с выделением теплоты. Спиртовое брожение является основой основ виноделия. При температуре +12 — +14С. и выше, на поверхности сусла появляются пузырьки углекислого газа — это признак начавшегося брожения.

|

Через день-два брожение становится бурным. На поверхности образуется масса пены. Постепенно, спустя две-три недели, брожение затихает и, наконец, совсем приостанавливается.

Вместо сладкого сока получается жидкость, лишенная сахара, но обогащенная спиртом. Это уже вино.

Следует отметить, что при приготовлении молодых фруктовых вин виноград перед брожением не давят, и переход сахара в алкоголь осуществляется внутри ягод. Брожение проходит всегда вместе с кожицей, ее красящие вещества растворяются в сусле и определяют цвет вина. Брожение длится 9—15 дней, иногда до трех недель, при строго контролируемой температуре — не выше + 30°С.

В зависимости от содержания сахара в винограде, при брожении получают вина разной крепости, которая исчисляется в градусах или в объемных процентах (% об.). Один процент сахара в отжатом сусле дает при брожении 0,6% об. Спирта. Таким образом, виноград, поступивший на переработку с базисной сахаристостью 18%, после полного сбраживания дает вино крепостью 10,8% об., то есть столовое.

Кроме сахара виноград содержит кислоты — винную, яблочную, лимонную, без которых он был бы, хотя и сладким, но невкусным. Это соотношение между сахарами и кислотами определяет вкус винограда, влияя на оценку вин любого типа — столовых, крепких, шипучих.

|

Виноградное вино является очень сложным соединением, число входящих в него элементов — около 600. Есть вина, приготовленные с добавлением спирта, так называемые крепленые, или спиртованные. Спирт, применяемый в виноделии, должен быть ректификованный — очищенный от примесей, без каких-либо посторонних вкусов и запахов.

|

Введение в бродящее сусло спирта дает возможность приостановить брожение на любой его стадии и этим сохранить несброженным заранее намеченное количество сахара.

Спиртованием можно повысить крепость вина до определенных величин, характерных для данного типа и сорта. Если во время созревания винограда было мало солнечных дней, и его урожай недостаточно хорош, в некоторых странах разрешены добавки сахара.

Когда брожение заканчивается, и большинство сахара превращается в алкоголь, чан спускают, и стекает первое, наиболее качественное вино. Оставшееся содержимое чана прессуют, получая «первый пресс», содержащий много танинов. Можно отжать и «второй пресс», но его в дальнейшем производстве, как правило, не используют.

«Самотек» (вино, стекшее само без прессовки) и «первый пресс» смешивают, количество последнего зависит от желаемой структуры вина. После этого при производстве дешевого, молодого вина, его переливают в металлические чаны, затем фильтруют и разливают по бутылкам.

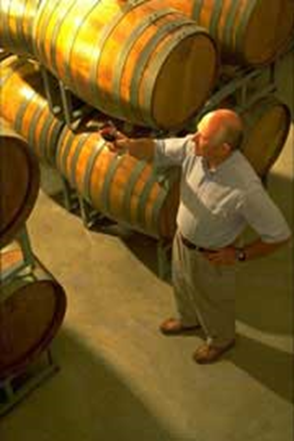

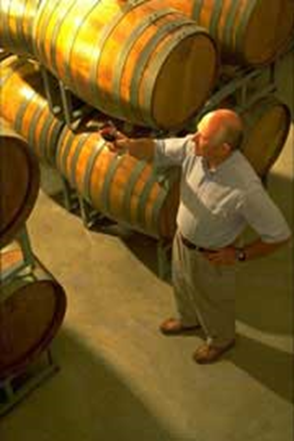

Дорогое вино выдерживается в погребе, в дубовых бочках, придающих ему дополнительные ароматы. Из-за испарений винодел постоянно должен доливать бочки вином, чтобы не допустить его окисления от контакта с воздухом. Осадок, образующийся во время выдержки, постепенно опускается на дно, и вино необходимо переливать в чистые бочки, и так четыре раза в год. Всего же старение длится от одного до двух лет и более.

Вина, выдержанные год и менее, называются ординарными, выдержанные более года-двух — марочными. После выдержки вино осветляют при помощи так называемой «оклейки»: в него вводят казеин или яичный белок, образующие нерастворимый осадок с нежелательными веществами.

Затем вино пропускают через механический фильтр и разливают по бутылкам. Как правило, хорошо очищенные вина не способны впоследствии улучшить свое качество, хотя они лучше переносят транспортировку и перемену температур, в то время, как слабоосветленные вина легко уязвимы, но хорошо стареют в бутылках, развивая при этом дополнительные ароматы. Это подтверждается тем осадком, который присущ дорогим высококачественным винам, требующим декантирования.

Белые вина получают как из белого, так и из красного винограда, например, для производства шампанского используется красный сорт Пино Нуар, а для Божоле Бланк — Каме. Основное отличие производства белых вин заключается в том, что раздавленные ягоды прессуют до брожения, и сусло бродит без кожицы. Для высококачественных белых вин используется только «самотек», для других же может применяться и «первый» и «второй пресс». Температуру брожения снижают до + 13—20°С.

Длительное брожение при низкой температуре дает более тонкое, фруктовое вино. Разливают белое вино по бутылкам раньше, чем красное, обычно его не выдерживают в дубовых бочках более 1, 5 лет. Розовое вино изготавливается из красного винограда, при этом сусло остается в контакте с кожицей несколько часов, затем ее отделяют. За исключением некоторых шампанских вин, розовое вино не следует делать из смеси красного и белого винограда.

На каждом этапе создания вина от опыта винодела, его знаний и честности зависит качество конечного продукта. Здесь важно все: выход вина с гектара виноградника (количество, как известно, мешает качеству), аккуратный сбор урожая, тщательный контроль брожения, не слишком сильная фильтрация, хорошее «воспитание вина» и многое другое.

Настоящее вино изготовляют только из винограда. Технические сорта винограда, идущие на производство вин, должны удовлетворять особым требованиям: хорошо накапливать сахар, иметь умеренную кислотность, хорошо поддаваться переработке, созревать в разное время.

Белые вина готовят из винограда с повышенным содержанием ароматических веществ и кислот, красные - с высоким содержанием красящих веществ и фенольных соединений. Высокосахаристые и ароматичные сорта используются для выработки десертных и ликерных вин. Для крепких вин хороши высокосахаристые сорта с пониженным содержанием кислот, большим количеством экстрактивных и фенольных веществ.

Для виноградных вин, изготовленных без каких-либо добавок, иногда применяется наименование «натуральное вино». Обычно это сухие и полусухие вина. С использованием различных добавок изготовляются ароматизированные вина. Это группа вин, приготовленная смешением виноматериалов, этилового спирта-ректификата или виноградного спирта, сахарного сиропа и настоев ингредиентов, придающих им специфический вкус и аромат.

Основным типом ароматизированных вин является вермут. Для ароматизации вин, кроме настоев ингредиентов, используют спиртовые растворы эфирных масел (эссенции), душистых веществ (например, ванилина), бальзамы и ароматные спирты. В старину такие вина называли пряными. Из других добавок интересны витамины.

Витаминизированные вина разрабатывались, в частности, во время Великой Отечественной войны для лечения раненых в эвакогоспиталях. Производства вина включает две стадии. На стадии первичного виноделия выполняются все операции, связанные с переработкой винограда, которые завершаются получением молодого вина. На стадии вторичного виноделия виноматериал обрабатывают, выдерживают и разливают в бутылки.

Собранный виноград поступает на дробление и прессование. Для получения шампанского его иногда прессуют гроздями. Сусло, вытекающее из винограда при легком отжиме без прессования, а также вино из него называется самотеком.

Для выработки белых вин сусло быстро отделяют от мезги. Такая технология называется переработкой по белому способу. Самотек и сусло первого давления идет на приготовление высококачественных вин, а последующие прессовые фракции - на выработку ординарного вина.

При переработке по красному способу необходимо извлечь красящие вещества из кожицы виноградных ягод. Для этого применяют разные приемы: нагрев мезги, брожение сусла на мезге, спиртование и брожение мезги с извлечением красящих веществ и другие приемы.

С античного времени известно сульфитирование сусла введением небольшого количества двуокиси серы с целью подавление вредных микроорганизмов. Без этого приема невозможно получить стабильное вино, способное к хранению. Далее сусло осветляют и направляют на брожение.

Брожение проводится на чистой культуре винных дрожжей или на природных дрожжах. Если надо получить сухое вино, то сахар сбраживается полностью. При выработке полусладких или сладких вин брожение принудительно останавливают разными способами: спиртованием, холодом или теплом.

После окончания брожения вино осветляется, его снимают с дрожжей путем переливания. Во время переливки смешивают вина одного типа и сорта. Период от конца брожения до первой переливки называется формированием вина. Для производства специальных вин используются особые технологические приемы.

Полученное молодое вино направляют на выдержку, а после окончания выдержки зрелое вино - на розлив, который обычно производится на автоматических линиях с минимальным доступом воздуха.

ВЫДЕРЖКА ВИНА - это длительное хранение вина в условиях, способствующих улучшению его качества. Вино, находящееся на выдержке длительное время, приобретает качества, свойственные готовому вину.

При выдержке протекают сложные процессы созревания (в бочках в присутствии воздуха) и старения (в бутылках без доступа воздуха) вина. Процесс выдержки с химической стороны очень сложный. Кроме кислорода, который нужен для достижения вином бутылочно-разливной зрелости (разливостойкости), в нем принимают участие превращения органических кислот, образование сложных эфиров и реакции отдельных веществ между собой.

Закладка вина на выдержку производится до 1 апреля, а сроки выдержки исчисляются с 1 января следующего за урожаем года. Вино на выдержке подвергается ряду технологических операций: дозирование двуокиси серы, кислорода, обработка стабилизаторами, холодом, теплом, фильтрация, купажирование, доливки, переливки и другие.

Оптимальная температура бочковой выдержки для разных типов вин - от 11° C до 18° C, влажность - около 85 %. Производится она в специальных винных подвалах, искусственных или приспособленных подземных помещениях. В таких подвалах отсутствуют суточные и сезонные колебания температуры, что обеспечивает оптимальный температурный режим. Для бочковой выдержки используют бочки, буты (очень большие бочки) и эмалированные резервуары. Срок бочковой выдержки различен для разных типов вин и составляет от 1 до 6 лет, а иногда и более.

После окончания бочковой выдержки и разлива в бутылки, марочные вина высокого качества выдерживают в бутылках. Коллекционные вина выдерживают в бутылках не менее 3 лет. Ординарные вина поступают на рынок, не подвергаясь бутылочной выдержке. В процессе выдержки без доступа кислорода вино приобретает тонкий букет бутылочной выдержки. Бутылочная выдержка портвейнов и многих десертных вин длится 20-30 и более лет.

Бутылки укупоривают длинными корковыми пробками без пор на донышках. Для предупреждения развития плесени пробку покрывают защитным составом. Чтобы исключить подсыхание пробки, бутылки с вином укладывают горизонтально в специальные устройства-полки, рассчитанные обычно на 50-500 бутылок. Бутылки осматривают 2 раза в год и устраняют замеченные дефекты. При старении вина в бутылках образуется осадок.