| Язык |

Контейнер-танки из нержавеющей стали от ООО "УКР-ПРОМ-ИННОВАЦИИ"

Контейнер-танки являются неотъемлемой частью многих промышленных процессов, таких как производство продуктов питания, фармацевтики, косметики и других. Они обеспечивают сохранность и безопасность продуктов, сохраняя их качество и свежесть.

ООО "УКР-ПРОМ-ИННОВАЦИИ" является одним из ведущих производителей контейнер-танков из нержавеющей стали. Наша компания предлагает широкий ассортимент контейнер-танков различных размеров и конфигураций, которые отвечают самым высоким требованиям промышленности.

Преимущества контейнер-танков из нержавеющей стали:

Контейнер-танки из нержавеющей стали являются надежными и долговечными. Они имеют высокую коррозионную стойкость и могут использоваться для перевозки различных жидкостей, включая агрессивные и коррозионные среды. Кроме того, они обладают следующими преимуществами:

Легкость в управлении и транспортировке

Контейнер-танки из нержавеющей стали легкие и компактные, что облегчает их транспортировку и управление. Они могут быть установлены на различных транспортных средствах и перевозиться на большие расстояния.

Легкость в чистке и уходе

Контейнер-танки из нержавеющей стали легко моются и дезинфицируются. Это позволяет поддерживать их в чистоте и гигиенической безопасности.

Экологическая безопасность

Нержавеющая сталь, используемая для изготовления контейнер-танков, является экологически чистым материалом. Она не выделяет токсичных веществ и не загрязняет окружающую среду.

Долговечность

Контейнер-танки из нержавеющей стали обладают высокой степенью прочности и долговечности. Они могут использоваться втечение длительного времени, не требуя серьезного технического обслуживания или ремонта.

Сохранение качества продуктов

Контейнер-танки из нержавеющей стали обеспечивают сохранность и безопасность продуктов во время транспортировки и хранения. Они защищают продукты от воздействия внешних факторов, таких как свет, воздух, запахи и бактерии.

Универсальность

Контейнер-танки из нержавеющей стали могут использоваться для перевозки и хранения различных продуктов, включая жидкости, пастообразные и сыпучие материалы.

Соответствие стандартам качества

Контейнер-танки из нержавеющей стали от ООО "УКР-ПРОМ-ИННОВАЦИИ" соответствуют самым высоким требованиям качества и безопасности, установленным международными и отраслевыми стандартами.

Применение контейнер-танков из нержавеющей стали

Контейнер-танки из нержавеющей стали широко используются в различных отраслях промышленности, включая:

Производство пищевых продуктов

Контейнер-танки из нержавеющей стали используются для хранения и транспортировки различных продуктов питания, таких как молоко, соки, пиво, вино и другие напитки.

Фармацевтическая отрасль

Контейнер-танки из нержавеющей стали используются для хранения и транспортировки лекарственных препаратов, вакцин и других медицинских продуктов.

Косметическая отрасль

Контейнер-танки из нержавеющей стали используются для хранения и транспортировки косметических продуктов, таких как кремы, лосьоны, шампуни и другие.

Химическая промышленность

Контейнер-танки из нержавеющей стали используются для хранения и транспортировки различных химических продуктов, включая агрессивные и коррозионные среды.

Энергетическая отрасль

Контейнер-танки из нержавеющей стали также используются для хранения и транспортировки нефтепродуктов, газа и других энергетических ресурсов.

Водоснабжение и водоотведение

Контейнер-танки из нержавеющей стали используются для хранения и транспортировки воды, а также для очистки и утилизации сточных вод.

Сельское хозяйство

Контейнер-танки из нержавеющей стали используются для хранения и транспортировки сельскохозяйственных продуктов, таких как молоко, масло, растворимый кофе и другие.

Продукция ООО "УКР-ПРОМ-ИННОВАЦИИ"

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали, включая:

Контейнер-танки для перевозки пищевых продуктов

Контейнер-танки для перевозки химических продуктов

Контейнер-танки для перевозки нефтепродуктов

Контейнер-танки для перевозки газа

Контейнер-танки для перевозки воды

Контейнер-танки для перевозки сельскохозяйственных продуктов

Контейнер-танки для перевозки медицинских продуктов

Кроме того, мы можем изготовить контейнер-танки на заказ с учетом специфических потребностей и требований клиента.

Контейнер-танки из нержавеющей стали являются надежными и долговечными решениями для хранения и транспортировки различных продуктов. ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает высококачественную продукцию, соответствующую самым высоким стандартам качества и безопасности. Наши контейнер-танки обеспечивают сохранность и безопасность продуктов, сохраняя их качество и свежесть. Обратитесь к нам, чтобы получить более подробную информацию о нашей продукции и услугах.

Контейнер-танк из нержавеющей стали

Контейнер-танк из нержавеющей стали обьемом 30 000 литров от "Роза ветров"™.

Танк-цистерна – грузовая тара, используемая для транспортировки жидких и газообразных грузов. Его классическая конструкция представляет собой металлическую цистерну, заключенную в жёсткий каркас. Прочные стальные рамы по размерам совпадают с размерами стандартных сухогрузных контейнеров. Цистерни мультимодальны, т.е. при смене транспорта не требуется перетарка груза, достаточно просто переместить тару с одного транспорта на другой.

Стоимость контейнер-танка из нержавеющей стали обьемом 30 m³ 15000 $

Контейнер танк весит 1,8 т.

Длина контейнера 6000 мм.

Внутри контейнера две сплошных перегородки и три волногасителя.

Контейнеры для пищевых продуктов являются одним из ключевых элементов в производстве и хранении пищевых продуктов. Контейнеры-цистерны для перевозки пищевых продуктов должны обладать рядом особенностей, которые обеспечивают безопасность и сохранность продукта в процессе перевозки и хранения. Из-за этого, контейнеры-цистерны из нержавеющей стали все чаще применяются в пищевой промышленности.

Вот несколько преимуществ контейнеров танков из нержавеющей стали для пищевых продуктов по сравнению со стальными контейнерами-цистернами:

⬥ Устойчивость к коррозии: Нержавеющая сталь обладает высокой устойчивостью к коррозии, что делает ее идеальным материалом для контейнеров-цистерн, в которых хранятся и перевозятся пищевые продукты. Это гарантирует безопасность и качество продукта, а также продлевает срок службы контейнера.

⬥ Легкость в уходе: Нержавеющая сталь легко моется и дезинфицируется, что обеспечивает высокий уровень гигиены и защиты от бактерий и других микроорганизмов. Кроме того, такие контейнеры не требуют специального ухода и покрытия, что упрощает их эксплуатацию и снижает затраты на обслуживание.

⬥ Прочность и долговечность: Нержавеющая сталь является прочным и устойчивым материалом, что гарантирует долговечность контейнеров-цистерн. Они могут выдерживать высокие нагрузки и удары, что делает их надежными для перевозки и хранения пищевых продуктов.

⬥ Сохранность качества продукта: Контейнеры-цистерны из нержавеющей стали не взаимодействуют с продуктами, что гарантирует сохранность и качество продукта. Кроме того, они не впитывают запахи и не оставляют привкуса, что позволяет сохранять оригинальный вкус и аромат продукта.

⬥ Соответствие нормам и требованиям: Контейнеры-цистерны из нержавеющей стали соответствуют международным стандартам и требованиям к контейнерам для перевозки пищевых продуктов. Это гарантирует безопасность продукта и защиту его от внешних факторов.

⬥ Удобство использования: Контейнеры-цистерны из нержавеющей стали легкие и удобны в использовании. Они имеют специальные клапаны для удобства загрузки и выгрузки продуктов и ревизионные люки для удобства контроля и чистки внутренней поверхности. Кроме того, они могут быть оснащены различными системами контроля и мониторинга, что упрощает их использование и повышает безопасность перевозки продуктов.

⬥ Экономичность: Контейнеры-цистерны из нержавеющей стали являются более экономичными, чем контейнеры-цистерны из других материалов. Они требуют меньше обслуживания и не требуют периодического покраски и ремонта, что снижает затраты на их эксплуатацию и обслуживание.

⬥ Универсальность: Контейнеры-цистерны из нержавеющей стали могут использоваться для перевозки различных типов пищевых продуктов, включая жидкости, порошки, сыпучие продукты и т.д. Это делает их универсальными и удобными для использования в различных отраслях пищевой промышленности.

⬥ Привлекательный внешний вид: Контейнеры-цистерны из нержавеющей стали имеют привлекательный внешний вид и могут быть использованы в качестве рекламного инструмента для бренда и продукта. Они могут быть украшены логотипами и надписями, что помогает продвигать продукт и повышать узнаваемость бренда.

.jpg)

Доступна такая опция, как паровой нагрев контейнер-танка. Стоимость 1.5 т. $.

Контейнеры-цистерны из нержавеющей стали с паровой рубашкой - это специальные емкости для хранения и перевозки жидких продуктов, таких как пищевые масла, сиропы, соки, молоко и т.д. Эти контейнеры имеют рубашку, через которую проходит пар или горячая вода, что позволяет поддерживать заданную температуру внутри контейнера. Ниже приведены преимущества и сферы применения контейнеров-цистерн из нержавеющей стали с паровой рубашкой:

Преимущества контейнер-танков из нержавеющей стали с паровым нагревом:

⬥ Контроль температуры: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой обеспечивают точный контроль температуры жидких продуктов, что является важным фактором для сохранения их качества и свойств.

⬥ Безопасность продукта: Паровая рубашка предотвращает нагревание продукта сверх допустимой температуры, что снижает риск его порчи и обеспечивает безопасность для потребителя.

⬥ Долговечность: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой имеют высокую степень коррозионной стойкости, что обеспечивает долговечность и длительный срок службы.

⬥ Экономичность: Использование контейнеров-цистерн из нержавеющей стали с паровой рубашкой позволяет сократить затраты на энергию и уменьшить временные затраты на нагрев продукта.

⬥ Легкость использования: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой легки и удобны в использовании, имеют удобные отверстия для заполнения и выгрузки продукта, а также для подключения паровой рубашки.

Сфера применения контейнер-танков из нержавеющей стали с паровым нагревом:

⬥ Пищевая промышленность: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой широко используются в пищевой промышленности для хранения и перевозки жидких продуктов, таких как молоко, соки, сиропы, масла и т.д.

⬥ Фармацевтическая промышленность: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой также находят широкое применение в фармацевтической промышленности для хранения и перевозки различных жидких лекарственных препаратов, которые требуют точного контроля температуры.

⬥ Химическая промышленность: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой также используются в химической промышленности для перевозки и хранения различных жидких химических веществ, которые также требуют точного контроля температуры.

⬥ Косметическая промышленность: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой также используются в косметической промышленности для хранения и перевозки жидких косметических продуктов, таких как шампуни, гели для душа, масла и т.д.

⬥ Прочие отрасли: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой также могут использоваться в других отраслях промышленности, где необходимо хранение и перевозка жидких продуктов при определенной температуре.

⬥ Сохранение консистенции продуктов при перевозке: Контейнеры-цистерны из нержавеющей стали с паровой рубашкой также могут быть использованы для перевозки жидких продуктов, которые застывают при низких температурах, таких как рапсовое масло. Паровая рубашка позволяет поддерживать температуру в контейнере на определенном уровне, что позволяет сохранить консистенцию продукта и избежать его застывания. Это особенно важно при транспортировке продуктов на большие расстояния, где температуры могут быть ниже, чем оптимальные для хранения продукта.

В целом, контейнеры-цистерны из нержавеющей стали с паровой рубашкой представляют собой надежное и безопасное средство для хранения и перевозки различных жидких продуктов, которые требуют точного контроля температуры. Они широко применяются в различных отраслях промышленности, где важна сохранность и безопасность продукта. Контейнеры-цистерны из нержавеющей стали с паровой рубашкой позволяют сохранять температуру продукта на нужном уровне, что особенно важно для продуктов, которые застывают при низких температурах. Таким образом, использование таких контейнеров обеспечивает сохранность продукта и предотвращает его повреждение во время перевозки.

Использование танк-цистерн рентабельно и практично для следующих категорий предприятий:

⬥ транспортно-экспедиционные компании (логистка завод-клиент);

⬥ заводы-производители (сырьевые собственники с потребностью хранить/ возить продукцию своим клиентам, в филиалы);

⬥ строительные организации с собственной заправкой на объекте (перевозка, хранение, раздача топлива).

Танк-цистерна приспособлена для перевозок автомобильным, железнодорожным, морским путем, посредством стандартной погрузочной техники легко и быстро перегружается с одного вида транспорта на другой без доступа к грузу.

Представляет собой цистерну из нержавеющей стали, помещенную в металлический каркас 20/40-футового ISO контейнера. Стандартизированные габариты контейнера-цистерны позволяют перевозить жидкости по бесперевалочной технологии, обеспечивая максимальную сохранность груза, экономя средства клиентов, сокращая сроки доставки.

В зависимости от планируемого назначения, цистерны изготавливают из различных марок стали с разной толщиной стенки. В большинстве случаев эту продукцию производят из стали марок AISI 304 (нержавеющая кислостойкая сталь) или AISI 316 (особо устойчивая сталь с добавлением молибдена).

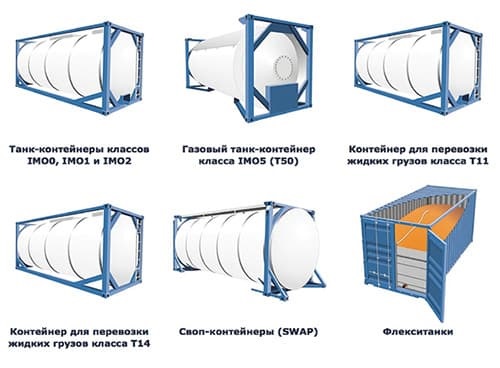

Назначение контейнеров-цистерн отражено в маркировке. Ранее использовалась классификация IMO. IMO 0, IMO 1, IMO 2 характеризуют виды танк-контейнеров, предназначенных для транспортировки жидкостей, IMO 5 – сжатых и сжиженных газов. Новый аналог этой классификационной системы – T-коды, регламентируемые Portable Tank Instruction.

IMO 0 (T0-T6). Эта группа предназначена для транспортировки и хранения пищевой продукции – воды, соков низкой концентрации, молока, масел, не требующих разгрузки под давлением. Толщина стенок металлической емкости – 2 мм. При необходимости может оснащаться теплоизоляционным слоем и/или системой пароподогрева. Такие тары применяются только для пищевых продуктов. Если же емкость была использована для доставки химической среды, даже безопасной, пищевые продукты в ней перевозить запрещено. Пригодность тары для перевозки продуктов определяется с помощью химанализа воздуха пустой цистерны.

IMO 2 (T7-T10). Блоки рассчитаны на доставку химических веществ, имеющих низкий класс опасности для человека и окружающей среды и допускающих нижний слив. Эта тара широко востребована при транспортировке пищевых продуктов. Толщина стенки – 3-4 мм. Возможно устройство теплоизоляционного слоя, электро-, пароподогрева.

IMO 1 (T11-T22). В такой таре допускается перевозить опасные химические среды, а также вещества в условиях повышенного давления. Это щелочи, кислоты, бытовая химия, нефтепродукты. Толщина стенки – 4-7 мм. Может присутствовать верхний слив, что определяется свойствами жидкого груза. При необходимости оснащают теплоизоляционным слоем, системой паро- или электроподогрева. Танк-цистерны IMO 1 могут применяться для транспортировки грузов, относящихся к группе IMO 2, но не наоборот.

IMO 5 (T50). Контейнеры-цистерны этой группы обеспечивают безопасную транспортировку легко воспламеняющихся веществ, в том числе сжиженных газовых сред, требующих соблюдения особого режима давления. Это пропан, бутан, сжиженный нефтяной газ и другие. Контейнеры, использованные для доставки газов, не могут применяться для транспортировки других сред.

Технические и сервисные характеристики определяют эффективность использования данной тары:

Мультимодальность — главное преимущество танк-контейнеров. Стандартизированные размеры контейнеров позволяют перевозить их автомобильным, железнодорожным, водным транспортом. При смене видов транспорта отсутствует перевалка груза, что значительно сокращает сроки перевозки, финансовые издержки, трудозатраты на разгрузочно-погрузочные работы.

Надежное хранение. Идеально подходят для хранения жидкостей на производстве после прибытия в пункт доставки. Танк-контейне не требует подготовленной площадки, легко и оперативно устанавливается на любой ровной поверхности, конструкция допускает складирование в несколько ярусов. Наличие нижнего слива позволяет выгружать жидкость частями.

Экономически выгодная тара. Стоимость аренды танк-контейнера ниже, чем тарифы на традиционную автомобильную или железнодорожную цистерну. Отсутствие перевалки в портах, на ж/д терминалах значительно сокращает продолжительность перевозки, транспортные затраты. Дополнительная экономия получается за счет бестарного способа перевозки, с удешевлением закупочной стоимости продукции. Пример: сравнение с перевозкой в 200-литровых бочках. Объем танк-контейнера составляет 23 000 литров, равен объему, разлитого в 115 бочек. Стоимость одной бочки — 1000 грн/штука. Выбирая танк-контейнер, достигается экономия 115 000 грн путем отказа от тары, килограмм поставляемого товара обходится дешевле.

Увеличенная грузоподъемность. Еврофура перевозит максимально 88 бочек (17 600 литров), вместимость танк-контейнера — 30 000 литров. Соответственно, три танк-контейнера заменяют четыре грузовика, позволяя экономить 25% на фрахте, погрузочно-разгрузочных операциях, документационной работе.

Удобная эксплуатация. Практичная конструкция контейнера-цистерны упрощает погрузку/разгрузку, слив, хранение, перемещение по производству.

Максимальная безопасность обеспечивается продуманной конструкцией, высокотехнологичными материалами, используемыми при производстве танк-контейнеров. Сам принцип бесперегрузочной технологии позволяет предотвратить риски загрязнения окружающей среды и обеспечить чистоту перевозимого продукта.

Виды контейнеров танков из нержавеющей стали.

Контейнер-танки для перевозки пищевых продуктов

Контейнер-танки из нержавеющей стали для перевозки пищевых продуктов являются надежными и безопасными решениями для хранения и транспортировки различных типов продуктов питания, таких как молоко, соки, вино, пиво, масло, соусы и другие.

Они обеспечивают сохранность и безопасность продуктов, сохраняя их качество и свежесть.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки пищевых продуктов различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки продуктов питания как на местном, так и на международном уровнях.

Контейнер-танки для перевозки химических продуктов

Контейнер-танки из нержавеющей стали для перевозки химических продуктов являются надежными и безопасными решениями для хранения и транспортировки различных типов химических продуктов, включая агрессивные и коррозионные среды.

Они обеспечивают безопасность и сохранность продуктов, предотвращая утечки и разливы.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки химических продуктов различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки химических продуктов как на местном, так и на международном уровнях.

Контейнер-танки для перевозки нефтепродуктов

Контейнер-танки из нержавеющей стали для перевозки нефтепродуктов являются надежными и безопасными решениями для хранения и транспортировки различных типов нефтепродуктов, таких как бензин, дизельное топливо, керосин, мазут и другие.

Они обеспечивают сохранность и безопасность продуктов, предотвращая утечки и разливы.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки нефтепродуктов различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки нефтепродуктов как на местном, так и на международном уровнях.

Контейнер-танки для перевозки газа

Контейнер-танки из нержавеющей стали для перевозки газа являются надежными и безопасными решениями для хранения и транспортировки различных типов газов, таких как пропан, бутан, природный газ и другие.

Они обеспечивают сохранность и безопасность продуктов, предотвращая утечки и разливы.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки газа различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки газа как на местном, так и на международном уровнях.

Контейнер-танки для перевозки воды

Контейнер-танки из нержавеющей стали для перевозки воды являются надежными и безопасными решениями для хранения и транспортировки различных типов воды, включая питьевую, техническую и промышленную воду.

Они обеспечивают сохранность и безопасность продуктов, предотвращая утечки и разливы.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки воды различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки воды как на местном, так и на международном уровнях.

Контейнер-танки для перевозки сельскохозяйственных продуктов

Контейнер-танки из нержавеющей стали для перевозки сельскохозяйственных продуктов являются надежными и безопасными решениями для хранения и транспортировки различных типов сельскохозяйственных продуктов, таких как молоко, масло, растворимый кофе, зерно, корм и другие.

Они обеспечивают сохранность и безопасность продуктов, сохраняя их качество и свежесть.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки сельскохозяйственных продуктов различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки сельскохозяйственных продуктов как на местном, так и на международном уровнях.

Контейнер-танки для перевозки медицинских продуктов

Контейнер-танки из нержавеющей стали для перевозки медицинских продуктов являются надежными и безопасными решениями для хранения и транспортировки медицинских продуктов, таких как лекарства, кровь, вакцины и другие.

Они обеспечивают сохранность и безопасность продуктов, сохраняя их качество и эффективность.

ООО "УКР-ПРОМ-ИННОВАЦИИ" предлагает широкий ассортимент контейнер-танков из нержавеющей стали для перевозки медицинских продуктов различного объема и конфигурации.

Наши контейнер-танки соответствуют международным стандартам качества и безопасности, и могут быть использованы для перевозки медицинскихпродуктов как на местном, так и на международном уровнях.

Контейнер-танки из нержавеющей стали от ООО "УКР-ПРОМ-ИННОВАЦИИ" являются надежными и безопасными решениями для хранения и транспортировки различных типов продуктов и материалов, включая пищевые продукты, химические продукты, нефтепродукты, газ, воду, сельскохозяйственные продукты и медицинские продукты.

Наша компания предлагает широкий ассортимент контейнер-танков из нержавеющей стали различного объема и конфигурации, соответствующих международным стандартам качества и безопасности.

Мы гарантируем надежность и безопасность наших продуктов, а также высокий уровень сервиса и поддержки клиентов.

Если вы ищете надежные и безопасные контейнер-танки из нержавеющей стали для перевозки и хранения различных продуктов и материалов, обратитесь в ООО "УКР-ПРОМ-ИННОВАЦИИ".

Мы будем рады помочь вам в выборе наилучшего решения для ваших потребностей.