|

| Язык |

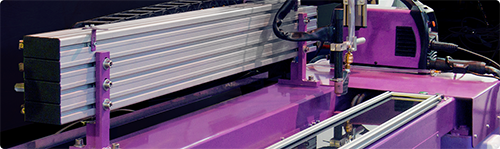

Станок для продольной TIG сварки труб.

Основная область применения станка: производство дымоходов из нержавеющей стали.

- Цифровое управление параметрами сварки через сенсорную панель Siemens.

- Современный и надежный сварочный инвертор Fronius и др. по запросу. В комплекте со сварочными горелками Abicor Binzel.

- Высокоскоростной серводвигатель.

- Изменяемая точка начала сварки по всей рабочей длине от 0,1 мм. Возможность изменения скорости в процессе сварки с автоматическим запоминанием нового значения.

- Функция прерывания и возобновления сварочного цикла.

- Большой выбор модификаций станка для решения различных задач.

Преимущество машины:

- Скорость сварки на аустенитной нержавейке до 6 м в минуту.

- Точность позиционирования 0.02 мм за счет высокоточного серводвигателя Panasonic.

- Предотвращение брака сварочного шва в случае не качественного свальцовывания (бочка образности) трубы происходит за счет прерывания процесса сварки и авто возврата в точку.

- Блок подачи присадочной проволоки (опция)

- Компенсатор деформации балки

Станок для продольной ТИГ сварки обечаек труб Проминь 1.

Станок предназначен для сварки нержавеющих, стальных и медных труб стык в стык. Используется для изготовления дымоходов, вентиляционных труб, обечаек для емкостей и ЦКТ, а также любых других изделий из нержавеющей стали длиной 1000 мм. Стоимость станка 15 500 евро.

|

При сварке изделий вмешательство оператора минимально. Заготовка автоматически зажимается пневматическими прижимами. Выставляется необходимая сила тока и скорость производимой сварки.

Горелка перемещается автоматически. При окончании сварки горелка поднимается и возвращается в исходное положение.

Далее, фиксирующие прижимы освобождают готовую трубу.

Станок способен сваривать нержавеющую сталь толщиной от 0.5 мм до 4 мм (в зависимости от установленного сварочного источника).

Станок способен работать всю рабочую смену без перерывов.

|

Мы производим обучение работников. Достаточно одного дня для того, чтобы работник мог самостоятельно выполнять все необходимые операции. Возможно оборудовать станок дополнительной опцией подачи сварочной присадки.

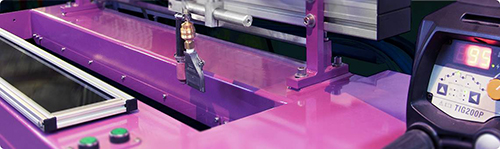

Поскольку аргон подается из двух точек сверху и с поддувом по всей длине снизу удается сохранить идеальный шов и снаружи трубы и изнутри. А медная подкладка по всей длине позволяет избежать перегрева металла и деформации.

|

Мы предлагаем станки для сварки обечаек длиной 500мм и 1000 мм, 1250 мм, 1500мм, 2000мм и 3000 мм.

Диаметры свариваемых изделий до 2500 мм.

Возможно изготовление станка с ЧПУ на базе контроллера Siemens simatic

|

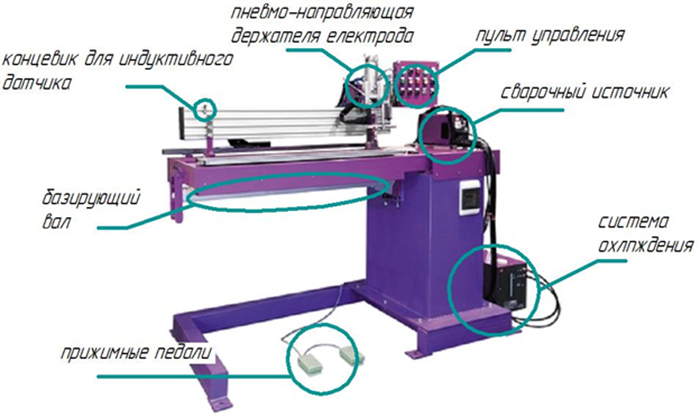

Сварочный источник - электронное устройство, которое обеспечивает питание сварочной цепи электрическим током. Заказчик может выбирать источник любой компании и мощности. На наши апараты мы рекомендуем ставить “Fronius”.

Система охлаждения – отвечает за поддержание температурных режимов при работе оборудования, проходя через сварочный рукав, а также через медный охладитель, находящийся в теле базирующего вала.

Прижимные педали – предназначены для базирования круглой заготовки на базирующем валу. Левая педаль отвечает за пневматическое опускание ряда медных прижимов, обеспечивая надежную фиксацию заготовки на валу. Правая - правого ряда медных прижимов.

Базирующий вал – изготовлен из высокопрочной каленой стали. Используется как базирующая поверхность заготовки и основа для “TIG” сварки.

Концевик для индуктивного датчика – это механический ограничитель линейного хода сварочной головы. Используется как для выставления нулевой точки для поджига сварочного электрода в определенной точке, так и для ограничения хода сварочной головы на необходимое растояние сварочного шва (перемещение необходимо при изменении длины свариваемой заготовки).

Пневмо-направляющая держателя электрода – отвечает за пневматическое поднятие и опускание сварочного держателя електродов, для безопасного перемещения всей рабочей головы вдоль рабочей зоны, а также для удобной смены сварочных електродов.

Пульт управления – это набор аналоговых кнопок управления работой сварочного оборудования. В нем присутствует потенциометр для выставления скорости перемещения сварочного электрода, ручное премещение электрода влево, вправо, кнопка начала сварки, кнопка возврата апарата в нулевую точку, аварийный стоп, а так же индикатор готовности оборудования к работе.

Подробное описание принципа работы:

Провальцевав заготовку, оператор должен сбазировать ее на базирующем валу, для этого он поднимает фиксатор вала и заводит заготовку параллельно базирующей поверхности, таким образом, чтобы стык завальцованой заготовки совпадал с верхним центром вала. После этого оператор закрывает фиксатор вала и выставляет левую сторону заготовки паралельно центра медного охладителя, расположенного в верхней части базирующего вала.

После выставления параллельности левой стороны заготовки оператор фиксирует ее с помощью левой педали. Убедившись, что заготовка находится в правильном положении, оператор, не отпуская педали, нажимает стопорную кнопку, чем оставляет закотовку в зажатом положени (стопорная кнопка находится справа от оператора под правой рукой). После этого оператор прислоняет правую (свободную) сторону заготовки к левой стороне детали, таким образом формируя не сваренное соединение двух концов детали, и прижимает ее с помощью правой педали, как было описано выше.

Когда деталь полность сбазирована, оператор проверяет совпадение центра сварочного электрода с началом заготовки (с помощью клавиш «влево», «вправо» он может перемещать сварочный держатель вдоль оси сварки. Для более точной отладки сварочный держатель електродов крепится на координатный стол, который дает возможность оператору, с помощью маховиков, откорректировать точное положение сварочного электрода).

Это положение и будет положением начала сварки, в это положение он и подводит один из индуктивный концевик напротив индуктивного датчика отвечающего за поджиг электрода. Второй концевик устанавливается за 10-15 миллиметров от точки начала сварки и является нулевой точкой (стартовой точкой) начала движения горелки.

Концевик устанавливается в конце заготовки и будет означать точку выключения сварочного электрода (выставляется по длине заготовки). Важно: выставления концевиков нулевой и стартовой точки выставляются единожды и не требуют перевыставления в последующей работе оборудования.

Следующий этап – это непосредственно сама сварка заготовки. После выставления всех точек оператор должен выбрать необходимые параметры для сварки на сварочном источнике (выставление читайте в инструкции к сварочному источнику). После выбора параметров сварки, оператор с помощью кнопки, опускает электрод к заготовке в рабочее положение, подимает защитное стекло и нажимает кнопку «старт»: станок начал сварку и ведет шов со стороны крепления вала в сторону зажима базирующего вала.

Во время работы оператор может регулировать скорость перемещения электрода (если это необходимо) с помощью потенциометра, расположеного на панели управления, а также корректировать отклонения электрода с помощью маховиков координатного стола (если это необходимо), также у него присутствует кнопка «пауза» (если во время работы оператору необходима приостановить сварочный процес на какое-то время и продолжить его с точки, где электрод остановился) и кнопка «стоп» (останавливает сварочный процесс).

После завершения сварки оператор нажимает кнопку нулевой точки и электрод возвращается в исходное положение. Оператору остается нажать две фиксирующие кнопки (которые пневматически держат заготовку на валу), поднять фиксатор вала и снять заготовку.

Характеристики сварочной установки:

♦ саморегулирующиеся зажимные губки с точечной опорой

♦ независимая работа передних и задних зажимных губок

♦ фиксация с промежуточным ходом, обеспечивающая быструю установку тонких листов металла без нахлеста

♦ охлаждаемая нижняя сварочная подкладка с подачей формовочного газа, простая процедура замены, конструкция соответствует особенностям задач, в частности геометрии, форме шва, типу используемого защитного газа, материалу и т.д.

♦ автоматическая блокировка замка

♦ стабильная длина дуги благодаря специальному ходовому механизму

♦ эргономичное расположение органов управления

♦ комфортабельный пульт управления

♦ высококачественные компоненты оборудования

♦ жесткий сварной корпус станка, допускающий транспортировку с использованием автопогрузчика и крана.

♦ подробное руководство по эксплуатации

Технические данные:

|

Пределы регулирования сварочного тока, А |

8...170(220) |

|

Пределы регулирования скорости сварки, мм/с |

3...50 |

|

Предельные отклонения траектории перемещения горелки, мм, не более |

±0.2 |

|

Привод механизмов фиксации кромок изделия и подъема горелки |

пневматич. |

|

Защитный газ |

Ar |

|

Давление сжатого воздуха, МПа, до |

0.4 |

|

Охлаждение сварочнй горелки и подкладки |

жидкостное |

|

Габаритные размеры помещения, занимаемого оборудованием установки, мм, не менее |

3000 х 2000 х 2500 |

Программное управление и диагностика состояния элементов установки осуществляется с помощью контроллера.

Базовая программа обеспечивает:

♦ перемещение и опускание горелки в начало шва,

♦ зажигание дуги при неподвижной горелке,

♦ перемещение горелки со сварочной скоростью,

♦ заварку кратера,

♦ подъем горелки и ее возврат в исходное положение на маршевой скорости.

В процессе работы установки контролируются:

♦ положение горелки,

♦ давление воздуха в пневмосети,

♦ срабатывание пневмоприжимов.

На новом пульте оператора имеется возможность:

♦ запуск программы сварки;

♦ остановка программы;

♦ временной остановки программы (Пауза);

♦ включение программы без сварки;

♦ автоматический возврат всех исполнительных механизмов в исходное состояние;

♦ перемещение горелки в ручном режиме;

♦ плавное регулирование параметров режима сварки;

♦ быстрая переналадка установки под сварку труб разной длины.

Имеются исполнения сварочной установки:

♦ с укороченной консолью для сварки обечаек длиной до 500 мм меньшего диаметра;

♦ с удлиненной консолью для сварки обечаек длиной до 1250 и 1500 мм большего диаметра.

♦ по отдельному заказу изготавливаются установки для сварки обечаек длиной 1000 мм диаметром от 70 мм.

♦ отдельное исполнение установки позволяет выполнять сварку металла толщиной от 0.3 мм.

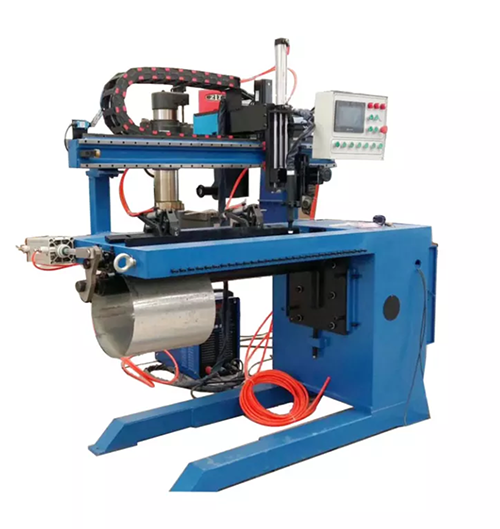

Позиция №2: Станок для сварки обечаек китайского производства:

|

Стоимость 14 тыс. Евро (включая НДС)

Условия оплаты:

70% предоплата

20% по прибытии станка в Украину

10% в течение 3-х дней после сообщения о готовности станка к отгрузке.

Срок поставки 45 дней. Также необходим срок для наладки.

Толщина свариваемого металла 0,5 – 2 мм.

Станок укомплектован сварочным источником 200А и охладителем.

Гарантийный срок 1 год.

Условия поставки EXW (Инкотермс 2010)