|

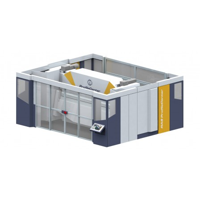

RAS MiniBend Center - это первый в мире автоматизированный гибочный центр для маленьких деталей. Развертка автоматически подается, подгибается и измеряется. Замена инструмента как и позиционирование развертки в нужном месте, производиться в автоматическом режиме. Гибочная траверса обладает функцией "up and down". MiniBendCenter - лидер по таким параметрам как "цена за деталь" и "производительность". Это очень гибкое оборудование, что позволяет без проблем эффективно изготавливать даже мелкие партии деталей. Интеллектуальная система загрузки заготовок с помощью промышленного робота не требует машинного обучения или программирования.

У нас Вы можете купить станки как оптом, так и в розницу. Гибкая система скидок и прекрасный сервис, соответствующий статусу брендов представленных нашей компанией, не оставят Вас равнодушными.

|

|

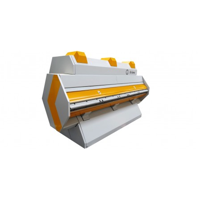

RAS Multibend Center продолжает устанавливать тенденции для поворотно гибочной технологии, используя динамический сервопривод, предельно быструю систему смены инструмента, технологию избежания царапин и гибкость вариантов инструментов. Гибкость, производительность, эргономика - все это подталкивает специалистов в гибке металла использоватьMultibend Center. |

|

RAS Multibend Center RAS 79.31-2. - Серия поворотно-гибочных станков. Этот станок готов работать с материалом длиной 3060 мм и толщиной 2 мм для обычной стали. Высота инструмента позволяет изготавливать достаточно глубокие коробки. Динамический сервопривод, предельно быстрая система смены инструмента,технология избежания царапин и гибкость вариантов инструментов подчеркивают уникальность Multibend Center. |

|

RAS Profile Center - это гибочный центр для листов габаритами до3200 мм в длину и 700 мм в ширину. Возможности гибочного центра позволяют работать с материалом до 2 мм для обычной стали и 1.5мм для нержавеющей стали. Profile Center использует поворотно-гибочную технологию для производства профиля дверных рам, частей лифтов и различных металлических шкафов. Высокая точность и продуктивность - это не проблема для данного оборудования. |

|

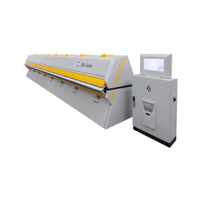

RAS UpDownCenter - это полуавтоматический гибочный центр для панелей и коробок длиной до 3200 мм, высотой до 250 мм и толщиной материала до 3 мм. Возможность гиба вверх и вниз, автоматическая система смены инструмента и система автоматизированного программирования - это основные преимущества этого оборудования. |

|

RAS XL-Center - Основан на используемой в XXL-Centerтехнологии, создан специально для крышных и архитектурных профилей. Ширина линии гиба - 3200 мм, толщина обрабатываемого материала - 1.5 мм для стали. При гибке листа вверх и вниз, эта модель станка сводит ручное вмешательство в процесс к минимуму. С программируемыми захватами возможно задавать линию гиба под углом к базирующей кромке. 300 градусов свободного пространства перед гибочными балками обеспечивают максимальную гибкость технологического процесса. 5сервоприводов и новый PC контроллер. |

|

RAS XXL-Center - Второе поколение специально разрабатывалось для строительной индустрии, чтобы дать своему владельцу уверенное преимущество над конкурентами. Преимущества начинаются с быстрой и удобной системы автоматизированного программирования. Оператору остается только загрузить лист метала на систему поддержки листов и нажать на педаль. RAS XXL-Center выполнит работу без сторонней помощи, что даст работникам время для упаковки продукции. |