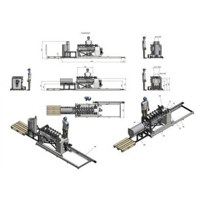

Lines for longitudinal-lateral cutting. Crosswise longitudinal cutting.

Line for manufacturing rectangular ducts

Wammes, Typ CL 1500 Ultra

.jpg)

This machine is designed specifically for the production of channels of rectangular cross-section and cross-cutting of sheet metal with a width of 1.500 mm.

Automatic control with the help of the VM facilitates the production of channels according to size, quantity and shape ("I, L, U" and "whole box" with adjustable folds). Controlled with the help of the High-Tech controller Siemens®.

The modular concept allows you to update the machine at any time with the help of a selection, punching module or exchange of a stiffening element.

|

|

Price per unit. |

|

|

Base module CL Ultra The correct and unified feed mechanism Z- or V-reinforced stiffener a shear and rounding module for the production of full cantilevers, L-taps or 4-sided (segmented in length) Adjustment, type S7-1200 Siemens, data entry through the touch screen |

|

56.700 € |

|

Options |

||

|

Uncoiler (Standard) 1.500mm Load capacity max. 5.000 kg |

|

3.240 € |

|

Sheet guide 4-fold 6-fold |

|

8.100 €

9.720 € |

|

Uncoiler frame 4 Winches 6 Winches |

|

2.430 € 3.240 € |

|

Elements of rigidity Z-profile V-profile Trapezoidal profile |

11.340 € |

|

|

Cutting module |

|

8.100 € |

|

Power shafts |

|

9.720 € |

|

Transverse profiling Pittsburgh Faltz (large) The catching seam |

|

51.840 € |

|

Side discharge Pittsburgh Faltz (standard) |

|

32.400 € |

|

High-power sealing pumping system |

|

25.920 € |

|

The material savings program for the Siemens® controller |

6.318 € | |

|

Continuous production |

1.620 € | |

Specifications

|

Material |

Uncoated and galvanized steel 0,5 – 1,25mm (1,5mm) (DX51D+Z275MA-C (DIN 10327) |

|

Roll weight |

Max. 5.000 kg |

|

Roll width |

Max. 1.500 mm |

|

Channel Type |

Fully bended, L-bend, 4-piece |

|

Min. channel size |

100 x 140 mm (closed channel) |

|

Max. channel size |

Theoretically never-ending, depending on the ease of use |

|

Element of rigidity |

Z-profile, V-profile or trapezium profile |

|

Adding a fold |

Adjustable addition of materials for various types of folds |

|

Hydraulics |

Hydraulic servo drive Brevini |

|

Electrics |

3 x 380 V; 25 A |

|

Control system |

Autonomous control panel with integrated, industrial control system Siemens® S7-1200 Control via touch screen and buttons |

|

Dimensions |

Depending on the choice of the module |

|

The weight |

Depending on the choice of the module |

|

Colour |

Blue RAL 5003 & Yellow RAL 1003 |

.jpg)

.jpg)

.jpg)

.jpg)